RoboBoat or International RoboBoat Competition (IRC) is a competition that invites participants to tackle simplified versions of challenges facing the modern maritime industry and roboBoat is an international student competition teams from around the world design autonomous, robotic boats (or ASVs) to navigate through a challenge course.

Aside from demonstrating some impressive maritime manueverability, these student-built boats are designed to tackle tasks that mimic real-world challenges facing the maritime industry. These challenges include coastal surveillance, port security and other types of oceanographic operations.

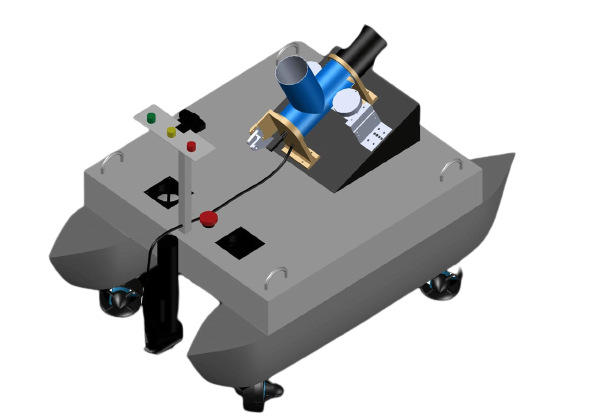

MRT PURVI ASV Is the first ship made by Barelang-MRT, the meaning of the word purvi comes from sansekerta languange, wihich has the meaning of 'First' with hope this will be a good first hope for the Barelang-MRT team.

International Robotic Competition (IRC) is the first competition participated by the Barlang-MRT team

Technical Design Report

We create catamaran type with length 1 meter, breadth/beam 0,6 meters,depth 0,18 meters,draft water line 0,12 meters. the goals is more stable when floating in water and have large enough loading space to install supporting components of the ship.

We have been negotiating for a long time, we chose the catamaran type using maxsurf software, because this ship is more stable when floating in water and has large enough loading space to install supporting components.

We use laser cutting to cut the station. going to next step we create a ship frame bg arranging frames in order, so attach stiffners as a booster. Doing skinned,putty fiber after the ship frame is ready the hulled ship`s frame using balsa wood with thickness balsa wood 1 mm. then if there will be small crack to cover it we are going to use fiber with resin mixture,then wait 1 or 2 days until the fiber is dry. then the fiber is lifted from the mold, the last our ship Already to sea trial

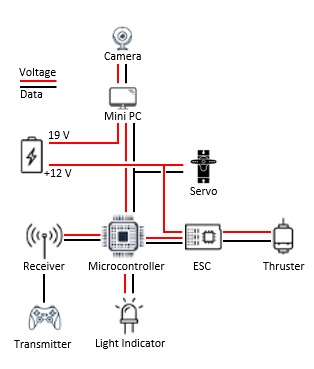

Electrical division we try to minimize the use of excessive wiring , it take up a lot of space on the boat.it use Arduino mega as the microcontroller with ultrasonic, sensor input,lidar,camera and receiver. It are also outputs t200 thruster, dc motor ,stepper motor, servo motor and several other components. To control the ship moving automatically.

For Artificial intelligence we use input in the form of camera, lidar and GPS module.

Ship testing is carried out to test whether the sensors and electronic systems on the ship are running well to complete the mission.

The ship, electrical components and programming have started in the raft where we compile the video one by one. Which will be taken by a non-technical team. Over time the video can be edited and we will make the video as interesting as possible. Here it is very important that there is no miscommunication with the team that results in small problems will be a big problem. So the key is building together to be a winner.